Surface Inspection Market worth $5.3 billion by 2026

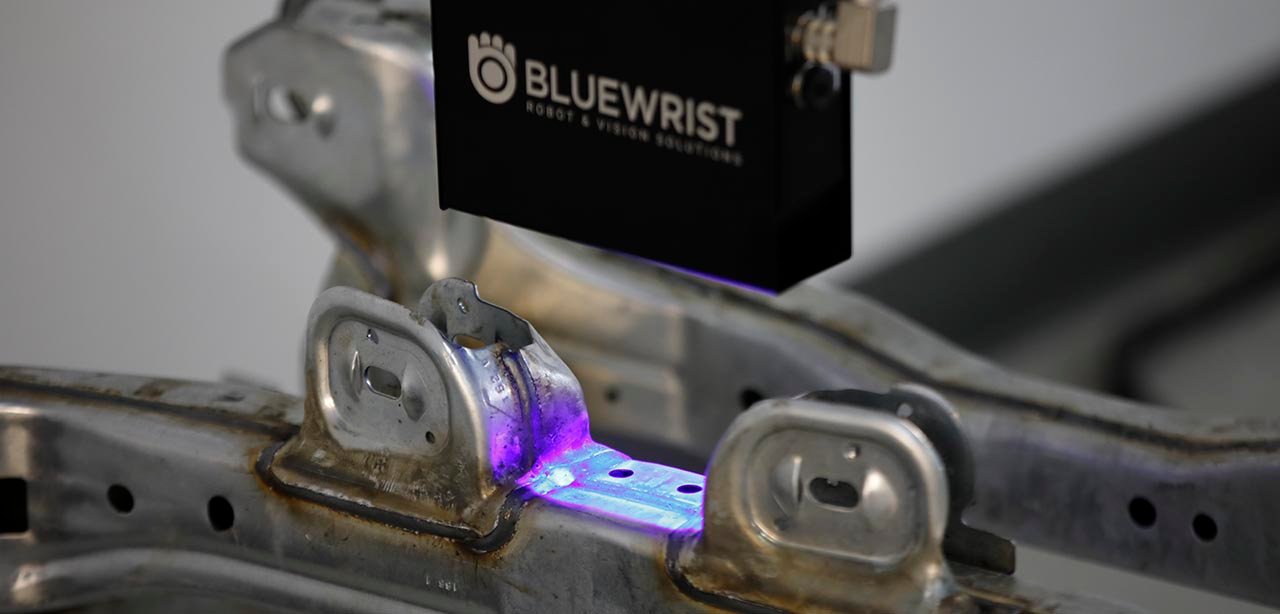

This article is related to the global surface inspection and quality control market. Bluewrist develops and deploys proven automated inspection solutions at the world’s leading OEMs and Tier-1 manufacturers to reduce downstream defects.

Read the full article on – PR News Wire Release by MarketandMarkets

Article Highlight:

“The automotive sector increasingly relies on highly effective surface inspection systems to prevent defects at various stages of production. Surface inspection systems capture various material and production-induced defects.”

“Software drives the image acquisition, processing, and analysis functions. If the application is high-speed, requiring excellent image quality and generating a lot of image data, software with good processing power and memory capabilities is required.”